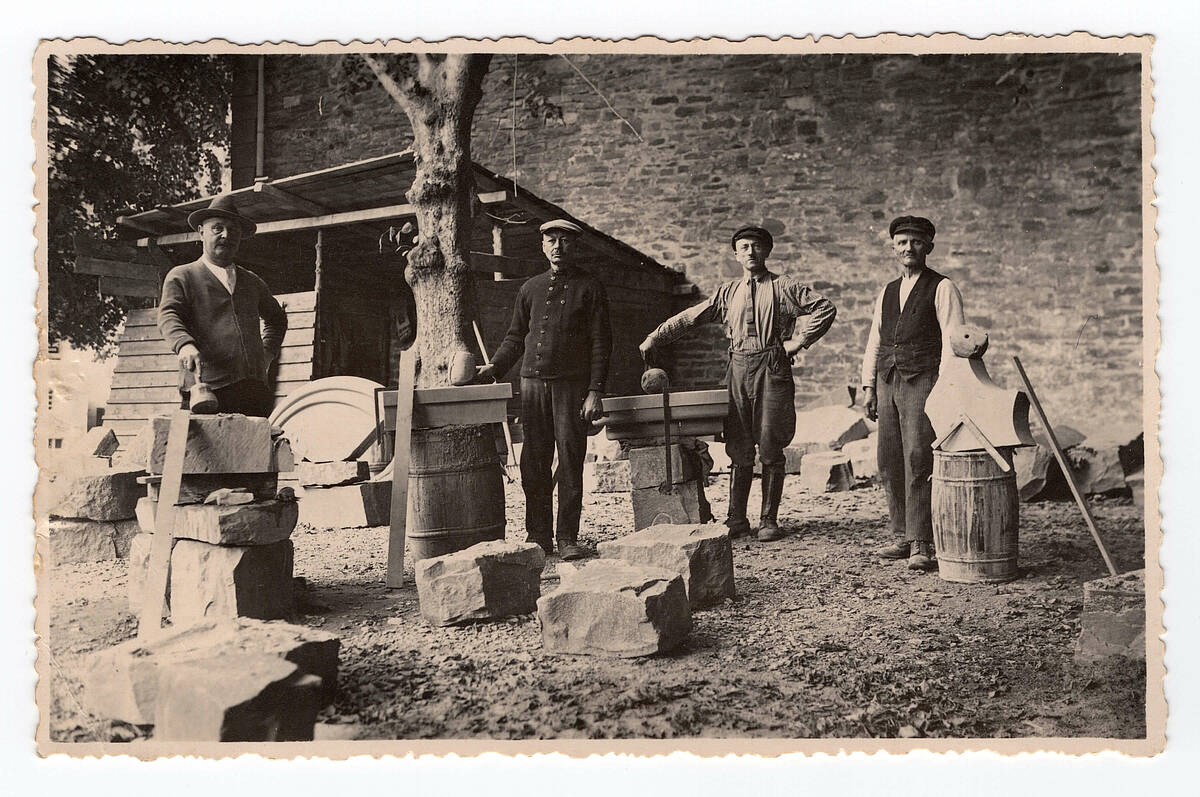

For centuries, Grauwacke served as an important building material along the rivers Agger, Leppe and Sülz. It was used for well shafts, foundations and cellar vaults. The area around Lindlar was crisscrossed by a dense network of small stone quarries, locally known as “Kauter”, where farmers, who were quarry owners, workers and masons all in one, extracted material for their own needs.

Commercial use of Grauwacke at Brungerst can be traced back as early as 1633. In that year, the pastor Gerhard Curmann and the churchwardens Adolff Moller and Chrest Foss signed a contract with the master stonemason Merten from Wetter near Marienheide. Necessary construction works for the St Severin Parish Church in Lindlar were to be carried out using local stones from “dem Brunhorst”. The origins of quarrying in the area are probably much older, but they are shrouded in the mists of Bergisch history.

For a long time, the poor condition of the roads made transporting Grauwacke to the cities along the rivers Rhine, Ruhr and Wupper nearly impossible. Only with immense effort could the heavy horse-drawn wagons pass along the old mountain paths. The situation only improved around 1850 with the construction of new roads in the valley lowlands. At that time, about 50 independent master stonecutters lived in Lindlar with their apprentices. They crafted delicately designed gravestone crosses, baptismal fonts and coat-of-arms stones. Many Lindlar families like Bremer, Klug, Lob and Offermann have been closely connected with Grauwacke for generations. Some stonecutters even found employment during the construction of Cologne Cathedral. Again and again it also brought foreign workers to the Lennefe. In the last 300 years, the old sources report on masters from Bavaria, from the Moselle and from the Palatinate, from Belgium, France and the Netherlands.

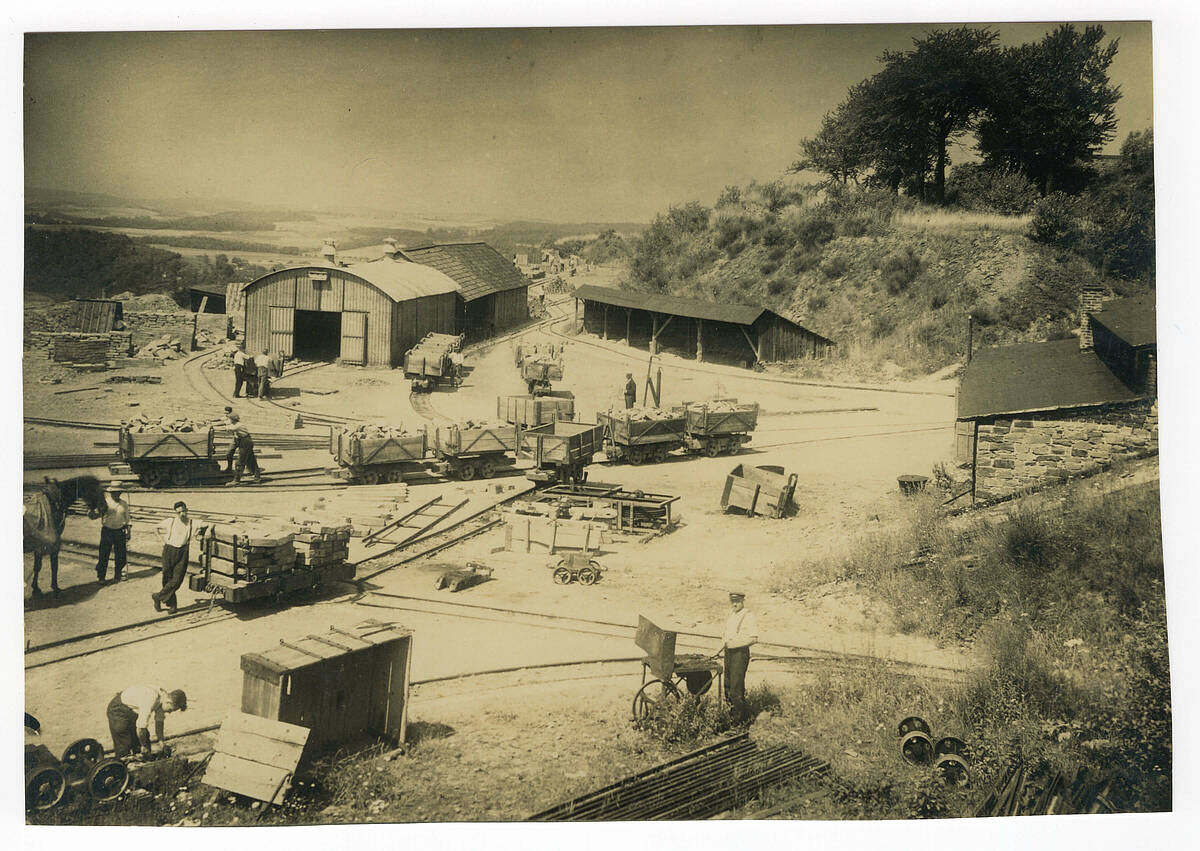

From 1871, industrialisation in the German Empire led to a unique economic boom. Cuboid cut stones from Lindlar found new markets in the construction of industrial plants and workers’ barracks. With advancing industrialisation, the Prussian Rhine Province was crisscrossed by an increasingly dense network of roads and railways. Grauwacke was now used as a base layer under roadways and railway tracks, as gravel and grit on avenues and highways, and as pavement on the boulevards and alleys of emerging industrial centres.

The new market promised high profits, leading to the rapid establishment of new quarries around Lindlar, Gummersbach and Marienheide. In 1874, the first operation was established in Gogarten near Wipperfürth. Other companies followed, such as the one in Alperbrück near Wiehl in 1878, Felsenthal near Lindlar in 1882, Talbecke near Gummersbach in 1892, and Kotthausen near Marienheide in 1893. Here, the focus was on fast and efficient mass production with increased use of machines. Even the previously unused waste material could be processed in crushers to produce profitable gravel.

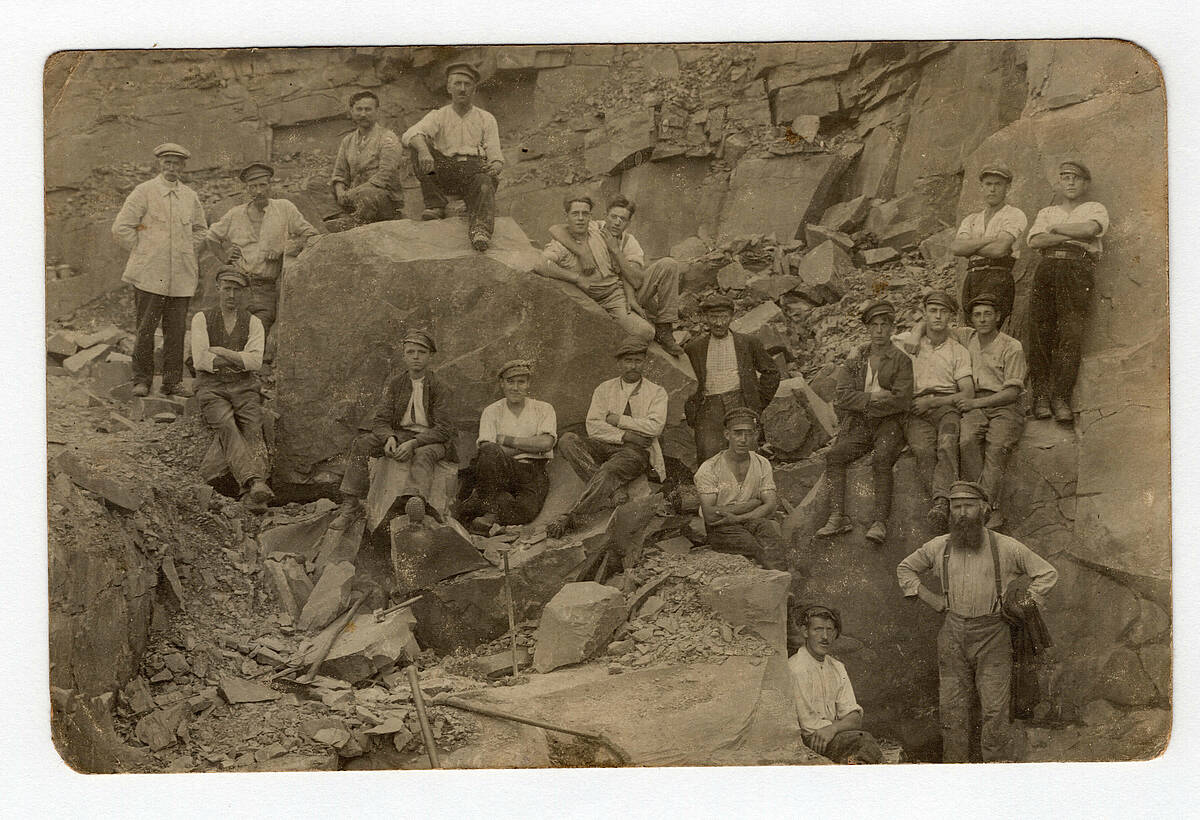

Before the First World War, Bergische Grauwacke was in high demand far beyond the borders of the German Empire. However, international competition was fierce: besides Westerwald basalt, Belgian sandstone and Swedish granite also entered the hotly contested market. Already in 1907, over 600,000 tonnes of affordable natural stones were imported from abroad, mostly by waterway. Quarry owners responded by modernising their operations. For the first time, pneumatic hammers, for example, came into use. However, even multiple protest notes to the relevant Ministry of Economic Affairs regarding the allegedly inferior stones from abroad could not defend their prominent market position.

Demand for cut stones decreased significantly, while the bulk business in paving stones, base layers and gravel also declined. Although the Rhenish Provincial Roads Association, a predecessor of today’s road authority Strassen NRW, required around 300,000 tonnes of Grauwacke a year to expand the road network. In the long term more vehicle-friendly road surfaces made of asphalt or tar prevailed with the spread of automobiles, motorcycles and lorries

Nevertheless, in the early 1920s, more than 250 people were employed at the quarry operation of Bergisch-Märkische Steinindustrie on Brungerst alone. With the onset of the 1929 Great Depression, most workers lost their income. It was only through the National Socialist autobahn construction projects that a slow revival of the struggling cut stone industry began around 1935. In the following years, numerous bridges and retaining walls were constructed or covered with stones from Bergische Grauwacke. At Brungerst, numerous tippers were exclusively involved in the precisely standardised production of the required cut stones and decorative plates.

During both world wars, prisoners of war and forcibly displaced civilians from their homelands were forced to do dangerous work in the quarries – often without experience, with poor food, and under inhumane conditions. In the Second World War, at least three quarries in Gummersbach, Marienheide and Wiehl had their own camps with over 800 forced labourers.

As early as 1933, a “wild concentration camp” of the SA was established for a short time on the premises of an abandoned cleaning wool factory in Wuppertal-Kemna. Here, well over 1,000 prisoners – Communists, Social Democrats, trade unionists and other political opponents of the National Socialists – were interned. Many were forced to perform hard physical and forced labour under sadistic supervision in the surrounding Grauwacke quarries.

![[Translate to English:] Illustration des Steinbruchbesitzers](/fileadmin/_processed_/2/b/csm_04-Der_Steinbruchbesitzer_6e931c22b0.png)